Improve Your Warehouse safety and compliance

Our warehouse safety and compliance bundle is delivered ready to use.

No time spent building templates, we deliver turnkey solutions

Proven Custom Warehouse Modules To Enhance Your Warehousing Business

Safety

Checklists

Induction & Training

Racking

Inspections

Contractor Management

Maintenance

Trusted Industry Solutions Delivering

Easy to use business tools to report, assess and share information.

Risks identified, action, monitor and review plans in place with your safety management system

Develop trends, gaps and opportunities to help accelerate business growth with Onesystem solutions.

Systems supports business growth, client satisfaction and employee retention.

No lock in contracts

10 tips to create a safer workplace

Warehouse safety needs to be a priority, finding the time to is often the challenge. A robust risk plan and adopting technology is the simplest way to improve your warehouse compliance to safety.

A risk plan takes a holistic approach to your business and task orientated approach to identify risk, existing controls, the additional controls required, who is responsible and how you monitor your performance. The risk plan is like an ongoing planner to drive performance and provide opportunity for continuous improvement.

- Tasks.

- Equipment.

- Training.

- Audits and planning.

- Emergency situations.

- What if scenarios.

So not every warehouse Is going to be designed specifically to meet your needs. But the way you move people and product though the warehouse can significantly increase OR decrease equipment interactions. It is this kind of Warehouse Compliance Management, which can potentially reduce manual handling.

- Office location.

- Racking layout and direction in relation to inbound and outbound doors and docks.

- Project demand and storage requirements.

- Picking and packing locations.

- Forklift charging and parking zones.

- People and forklift movements.

It’s a part of the legalisation, but more importantly meeting with teams and creating a collaborative approach bring people together creating a collective mind to solve proves, identify potential risks minimising business risks. Moreover, an engaged workforce is happier, more productive and likely have a higher retention rate.

- Daily meetings, what’s happening.

- Toolbox meetings.

- OHS committee meetings.

- Onboarding new client and product teams.

Having clear signage in place is the first step to increasing people’s situational awareness and setting the standard for your workplace and culture.

Signs to Consider:

- Car parking, visitor parking, office, all visitors must sign in.

- Emergency assembly points.

- Forklifts operating in this area.

- Driver safe zones.

- Speed limits.

- Emergency contacts

- PPE requirements, high visibility clothing, protective footwear.

- First aid kits, defibrillator,

- Emergency spill kits.

- Danger, battery charging, risk of explosion and gases.

- Emergency maps to be placed near exit points.

Key to a great warehouse management system, is keeping your staff, contractors and visitors trained and informed. This is an essential part in creating and maintaining a safe workplace:

- Inductions for Staff, Casuals, logistics and contractors (consider annual inductions).

- Notice boards to share information.

- Train people on core and high-risk tasks.

- Only competent and licensed people can operate mobile equipment (forklifts, pallet movers, order pickers etc).

- Create instructions for tasks.

People working around moving equipment creates a high-risk environment. A structured Warehouse Compliance Management system eliminates any safety issues.

Safety controls to consider:

- Traffic management plan.

- Traffic risk assessment.

- Barriers to segregate people and forklifts where possible.

- Inward folding gates in high traffic and cross over points.

- Clearly marked pedestrian walkways and crossings.

- Safety zone lighting on forklifts.

- Driver safe zones defined.

- Bollards and protective barriers.

PPE is low on the hierarchy of safety controls and plays a part in protecting people from harm. If your warehouse handles dangerous, flammable or hazardous goods, refer to the product safety data sheet for storage and handling requirements. To help with warehouse compliance PPE may include;

High visibility clothing.

Protective footwear.

Protective gloves.

A clean, tidy workplace reduces risks and creates a culture of safety and efficiency.

- Disposing of rubbish and recyclables immediately can reduce risk of slip, trips and falls.

- Keep work zones organised.

- Improve employee movement and efficiency by grouping similar items in a logical flow.

Optimise your equipment and rede risk by maintaining your equipment to manufacturers specifications.

- Maintenance schedule in place.

- Daily Warehouse Compliance checklists in place.

Monitor and review your performance with regular workplace inspections and systems audits. This promotes a pro-active culture with accountability and continuous improvement opportunities.

- Forklift daily checklist.

- Truck daily checklist.

- Licenses and training.

- Maintenance checks.

- Racking inspections.

- Pallet storage.

- Safety Reporting.

- Systems Audits.

- Traffic and Road.

- Traffic management.

- Workplace inspections.

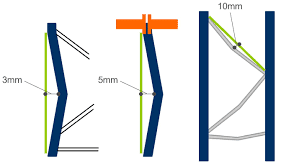

Racking Inspections

Racking Inspections are a Key Part to creating a Safe, Compliant Workplace and Protecting Stock

The Risk

- Empty racking is not good business.

- Any damage to pallet racking damage compromises the safety of your workplace placing people at risk.

- Racking damage impact racking integrity, increasing the risk of further damage, loss of storage space impacting revenue, stock loss and potential personal injury.

The Solution

- The solution reducing business risk and potential revenue reduction with regular inspections utilising Onesystem racking inspections and annual third-party inspections.

- Smart business partnering with Onesystem smart solutions.

Implement a Best Practice Warehouse Compliance Management System (CMS) into Your 3PL Operation

Onesystem’s Compliance Management bundle replaces the time consuming traditional 3PLS paper-based warehouse. Instead it provides a modern paperless operation, saving time, money and reducing business risks.

So for warehouse safety compliance, a dedicated implementation Manager streamlines the customisation of your system and site onboarding.

Our most popular bundle:

- Safety reporting and injury management

- Induction to Warehouse Compliance

- Daily forklift checklists

- Workplace Inspection

- Racking inspection